Loop Feed vs Radial Feed, Dead Front vs Live Front

When it comes to pad-mounted transformers, it's essential to choose the right setup based on your application. Today, let's dive into two key factors: the loop feed vs radial feed configurations and the dead front vs live front distinctions. These features not only impact the way transformers connect within a power distribution system but also play a crucial role in safety and maintenance.

Loop Feed vs Radial Feed

Radial Feed is the simpler of the two. Think of it as a one-way street for electricity. Power flows in one direction from the source to the transformer and then to the load. This configuration is straightforward and cost-effective for smaller, less complex systems. However, there’s one drawback: if the power supply is interrupted anywhere along the line, the entire system downstream loses power. Radial feed systems are best suited for applications where minimal redundancy is acceptable, and outages won’t cause significant issues.

On the other hand, Loop Feed is like a two-way street. Power can flow from either direction, creating a continuous loop. This design provides redundancy, meaning if there’s a fault in one part of the loop, power can still reach the transformer from the other side. Loop feed is ideal for more critical applications where system reliability is paramount. Hospitals, data centers, and other essential facilities benefit from loop feed configurations due to the added reliability and flexibility in switching.

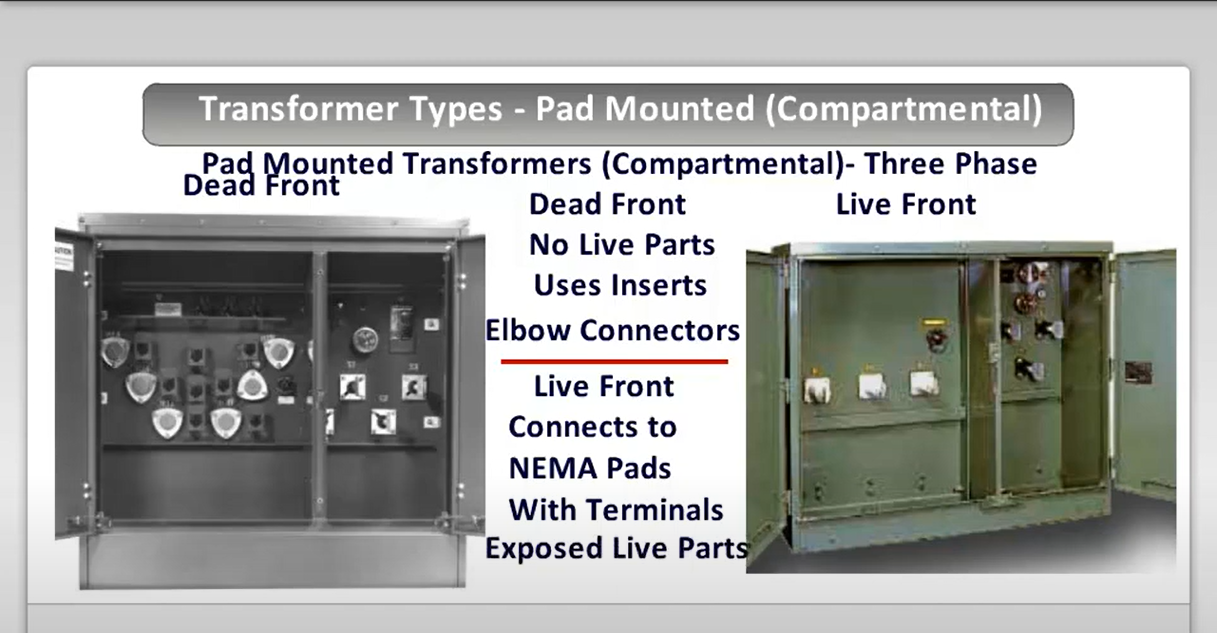

Dead Front vs Live Front

Now that we’ve covered how the transformer gets its power, let's talk about safety – dead front vs live front.

Dead Front transformers are designed with all energized parts safely enclosed or insulated. This makes them much safer for technicians who might need to perform maintenance or service the unit. There’s no exposed live equipment, which minimizes the risk of accidental contact with high-voltage parts. Dead front transformers are widely used in urban and residential areas, where safety is a priority for maintenance personnel and the general public.

In contrast, Live Front transformers have exposed, energized components such as bushings and terminals. This type of setup is more traditional and allows for easier access during maintenance, especially in older systems where service personnel are highly trained in handling live equipment. However, the downside is the increased risk of accidental contact or injury. Live front transformers are more commonly found in industrial environments where trained personnel can handle high-voltage equipment safely.

So, What’s the Verdict?

The decision between radial feed vs loop feed and dead front vs live front boils down to your specific application:

- If you need a simple and cost-effective solution where downtime isn't a major issue, radial feed is a great choice. But if reliability is key, especially for critical infrastructure, loop feed provides much-needed redundancy.

- For maximum safety and to meet modern standards, especially in public spaces or residential areas, dead front transformers are the way to go. Live front transformers, while more accessible for maintenance in certain settings, come with higher risks and are better suited for controlled environments like industrial facilities.

In short, choosing the right transformer setup involves balancing safety, reliability, and cost-efficiency based on the needs of your project. At JZP,we can help you find the perfect solution tailored to your unique requirements. Reach out to us for more information on how we can power your next project!

Post time: Sep-14-2024