When it comes to ensuring the efficient operation and longevity of power transformers, cooling is a key factor. Transformers work hard to manage electrical energy, and effective cooling helps them perform reliably and safely. Let’s explore some of the common cooling methods used in power transformers and where they are typically applied.

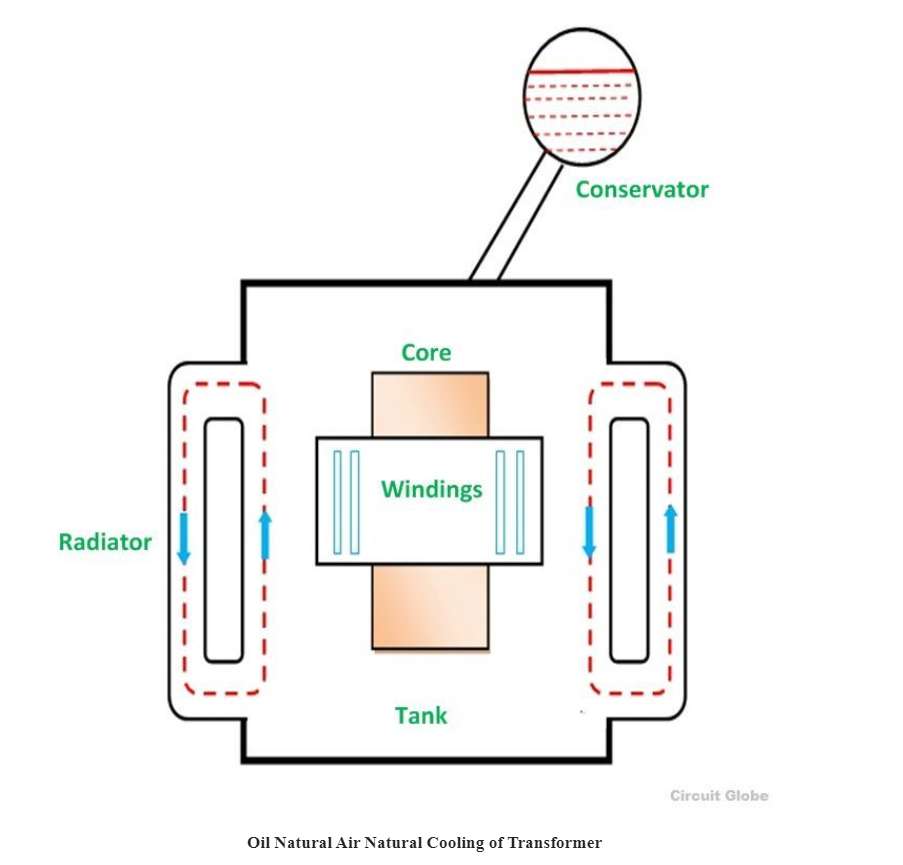

1. ONAN (Oil Natural Air Natural) Cooling

ONAN is one of the simplest and most widely used cooling methods. In this system, the transformer’s oil naturally circulates to absorb heat from the core and windings. The heat is then transferred to the surrounding air through natural convection. This method is ideal for smaller transformers or those operating in cooler environments. It’s straightforward, cost-effective, and relies on natural processes to keep the transformer cool.

Applications: ONAN cooling is commonly used in medium-sized transformers where the load is moderate and environmental conditions are favorable. It's often found in urban substations or areas with a temperate climate.

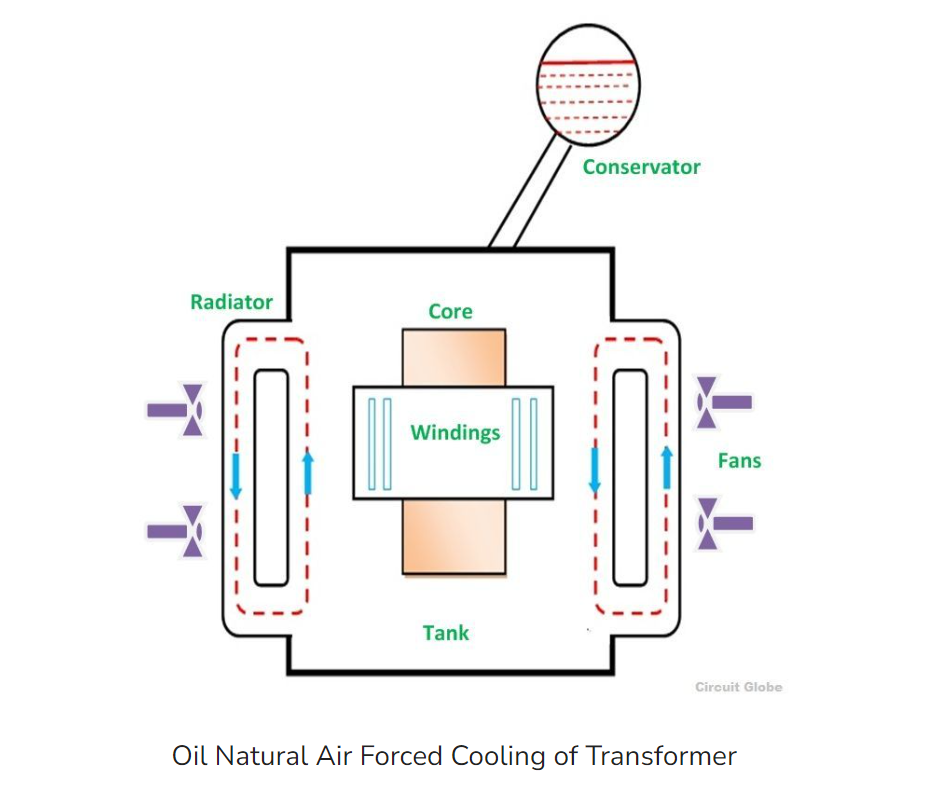

2. ONAF (Oil Natural Air Forced) Cooling

ONAF cooling enhances the ONAN method by adding forced air cooling. In this setup, a fan is used to blow air across the transformer’s cooling fins, increasing the rate of heat dissipation. This method helps manage higher temperatures and is suitable for transformers with a larger load capacity.

Applications: ONAF cooling is well-suited for transformers in locations with higher ambient temperatures or where the transformer experiences higher loads. You'll often find ONAF cooling in industrial settings or areas with warmer climates.

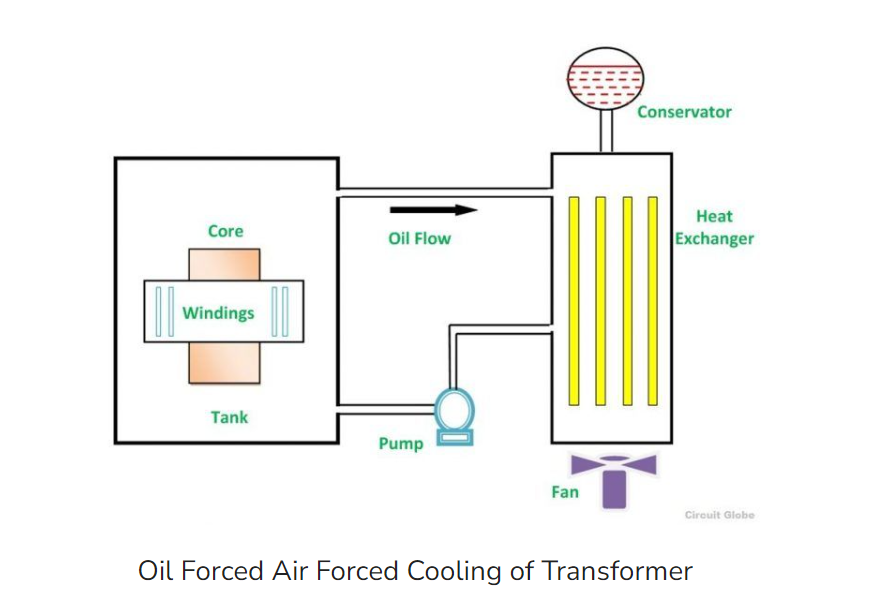

3. OFAF (Oil Forced Air Forced) Cooling

OFAF cooling combines forced oil circulation with forced air cooling. A pump circulates the oil through the transformer, while fans blow air over the cooling surfaces to enhance heat removal. This method provides robust cooling and is used for high-power transformers that need to handle significant heat loads.

Applications: OFAF cooling is ideal for large power transformers in heavy industrial applications or high-temperature environments. It’s often used in power plants, large substations, and critical infrastructure where reliability is crucial.

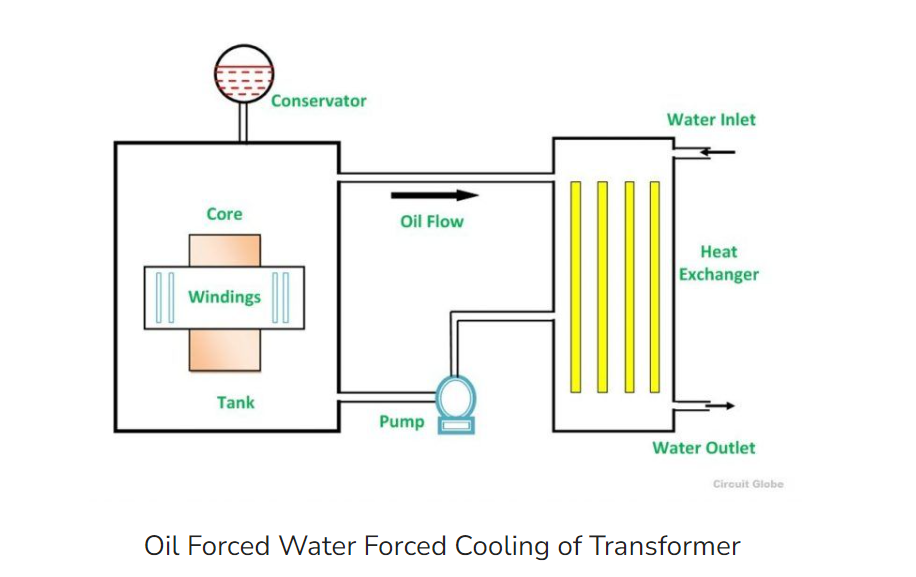

4. OFWF (Oil Forced Water Forced) Cooling

OFWF cooling uses forced oil circulation combined with water cooling. The oil is pumped through the transformer and then through a heat exchanger, where heat is transferred to circulating water. The heated water is then cooled in a cooling tower or another water-cooling system. This method provides high-efficiency cooling and is used in very high-power transformers.

Applications: OFWF cooling is typically found in large-scale power stations or facilities with substantial power demands. It’s designed for transformers that operate in extreme conditions or where space is limited.

5. OWAF (Oil-Water Air Forced) Cooling

OWAF cooling integrates oil, water, and forced air cooling. It uses oil to transfer heat from the transformer, water to absorb the heat from the oil, and air to help dissipate the heat from the water. This combination offers high cooling efficiency and is used for the largest and most critical transformers.

Applications: OWAF cooling is suited for ultra-high-capacity transformers in areas with extreme operational conditions. It's commonly used in major electrical substations, large industrial sites, and critical power transmission systems.

Conclusion

Choosing the right cooling method for a power transformer depends on its size, load capacity, and operating environment. Each cooling method offers unique benefits tailored to specific needs, helping ensure that transformers operate reliably and efficiently. By understanding these cooling methods, we can better appreciate the technology that keeps our electrical systems running smoothly.

Post time: Aug-23-2024