Transformer cores ensure efficient magnetic coupling between the windings. Learn all about transformer core types, how they are constructed, and what they do.

A transformer core is a structure of thin laminated sheets of ferrous metal (most commonly silicon steel) stacked together, that the primary and secondary windings of the transformer are wrapped around.

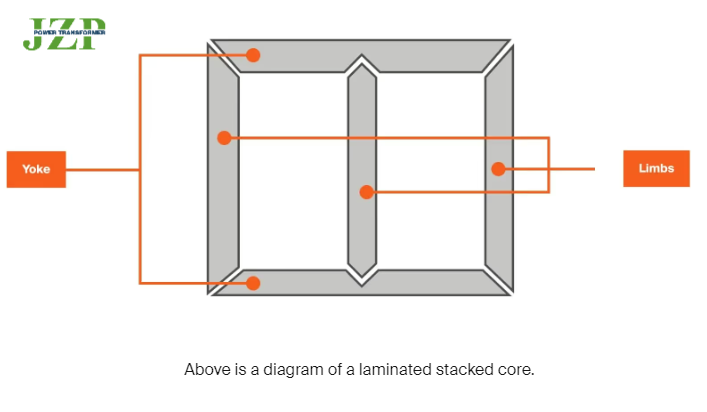

Parts of the core

A transformer core is a structure of thin laminated sheets of ferrous metal (most commonly silicon steel) stacked together, that the primary and secondary windings of the transformer are wrapped around.

Limbs

In the above example, the limbs of the core are the vertical sections which the coils are formed around. The limbs can also be located on the exterior of the outermost coils in the case of some core designs. The limbs on a transformer core can also be referred to as legs.

Yoke

The yoke is the horizontal section of the core which joins the limbs together. The yoke and limbs form a pathway for magnetic flux to flow freely.

Function of transformer core

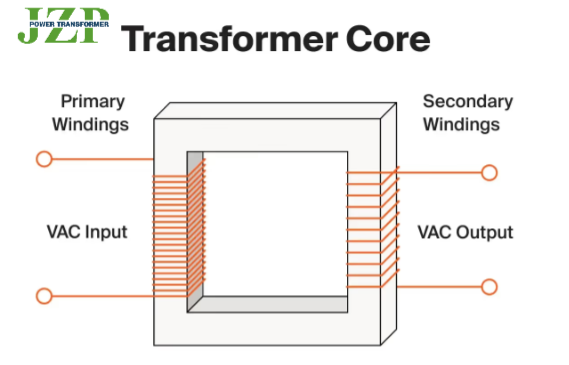

The transformer core ensures efficient magnetic coupling between the windings, facilitating the transfer of electrical energy from the primary side to the secondary side.

When you have two coils of wire side by side and you pass an electric current through one of them, an electromagnetic field is induced in the second coil, which can be represented by several symmetrical lines with direction emanating from north to south pole–called lines of flux. With the coils alone, the path of the flux will be unfocused and the density of the flux will be low.

Adding an iron core inside the coils focuses and magnifies the flux to make for a more efficient transfer of energy from primary to secondary. This is because the permeability of iron is much higher than that of air. If we think of electromagnetic flux like a bunch of cars going from one place to another, wrapping a coil around an iron core is like replacing a winding dirt road with an interstate highway. It’s much more efficient.

Type of core’s material

The earliest transformer cores utilized solid iron, however, methods developed over the years to refine raw iron ore into more permeable materials such as silicon steel, which is used today for transformer core designs due to its higher permeability. Also, the use of many densely packed laminated sheets reduces issues of circulating currents and overheating caused by solid iron core designs. Further increases in core design are made through cold rolling, annealing, and using grain oriented steel.

1.Cold Rolling

Silicon steel is a softer metal. Cold rolling silicon steel will increase its strength–making it more durable when assembling the core and coils together.

2.Annealing

The annealing process involves heating the core steel up to a high temperature to remove impurities. This process will increase the softness and ductility of the metal.

3.Grain Oriented Steel

Silicon steel already has a very high permeability, but this can be increased even further by orienting the grain of the steel in the same direction. Grain oriented steel can increase flux density by 30%.

Three, Four, and Five Limb Cores

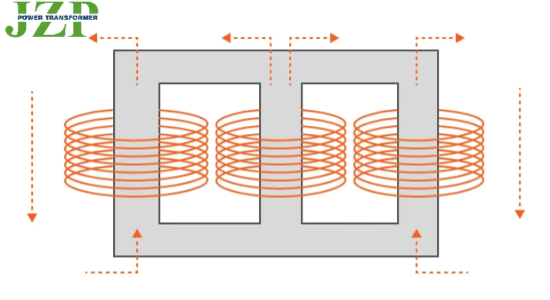

Three Limb Core

Three limb (or leg) cores are frequently used for distribution class dry-type transformers–both low and medium voltage types. The three limb stacked core design is also used for larger oil-filled power class transformers. It is less common to see a three limb core used for oil-filled distribution transformers.

Due to the absence of an outer limb(s), the three legged core alone is not suitable for wye-wye transformer configurations. As the picture below shows, there is no return path for the zero sequence flux which is present in wye-wye transformer designs. The zero sequence current, with no adequate return path, will attempt to create an alternate path, either using air gaps or the transformer tank itself, which can eventually lead to overheating and possibly transformer failure.

(Learn how transformers deal with heat through their cooling class)

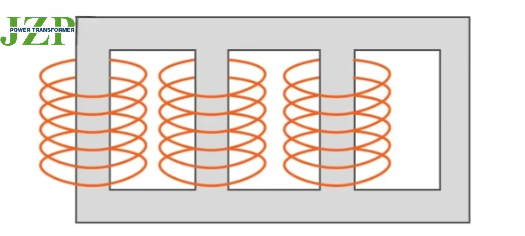

Four Limb Core

Rather than employ a buried delta tertiary winding, a four limb core design provides one outer limb for return flux. This type of core design is very similar to a five limb design as well in its functionality, which helps to reduce overheating and additional transformer noise.

Five Limb Core

Five-legged wrapped core designs are the standard for all distribution transformer applications today (regardless of whether or not the unit is wye-wye). Since the cross sectional area of the three inner limbs surrounded by the coils is double the size of the three limb design, the cross sectional area of the yoke and outer limbs can be half that of the inner limbs. This helps conserve material and reduce production costs as well.

Post time: Aug-05-2024