The bushing layout on substation transformers isn’t quite as simple as bushings on padmount transformers. The bushings on a padmount are always in the cabinet on the front of the unit with low-voltage bushings on the right and the high-voltage bushings on the left. Substation transformers can have the bushings located almost anywhere on the unit. What’s more, depending on the exact application, the order of substation bushings can vary.

All of this means that when you need a substation transformer, make sure you know the exact bushing layout before you place your order. Keep in mind the phasing between the transformer and the equipment you’re connecting to (breaker, etc.) The bushing layout has to be a mirror image, not identical.

How to choose layout of bushings

There are three factors:

- Bushing Locations

- Phasing

- Terminal Enclosures

Bushing Locations

The American National Standards Institute (ANSI) provides a universal designation for labeling transformer sides: ANSI Side 1 is the “front” of the transformer—the side of the unit that hosts the drain valve and nameplate. The other sides are designated moving clockwise around the unit: Facing the front of the transformer (Side 1), Side 2 is the left side, Side 3 is the back side, and Side 4 is the right side.

Sometimes substation bushings can be on the top of the unit, but in that case, they’ll be lined up along the edge of one side (not in the middle). The transformer’s nameplate will have a full description of its bushing layout.

Substation Phasing

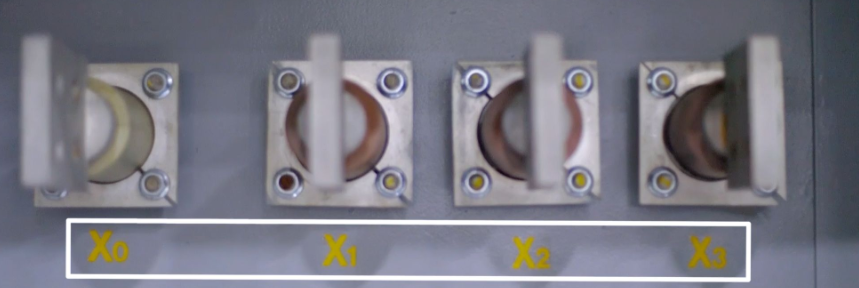

As you can see in the substation pictured above, the low-voltage bushings move from left to right: X0 (the neutral bushing), X1, X2, and X3.

However, if the phasing were the opposite of the previous example, the layout would be reversed: X0, X3, X2, and X1, moving from left to right.

The neutral bushing, pictured here on the left side, can also be located on the right side. The neutral bushing may also be located beneath the other bushings or on the lid of the transformer, but this location is less common.

Terminal enclosures

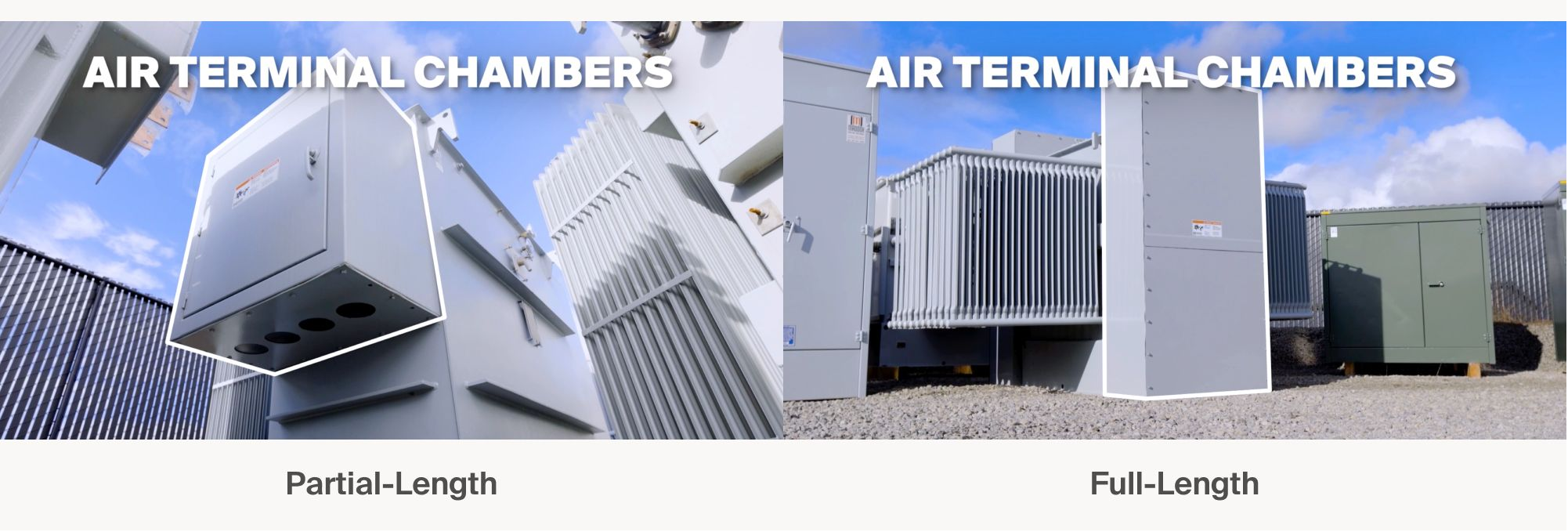

For the safety of anyone who might come into contact with a transformer, regulations require that all terminals be placed out of reach. Additionally, unless the bushings are rated for outdoor use—like top-mounted bushings—they must also be enclosed. Having the substation bushings covered keeps water and debris away from the live components. The three most common types of substation bushing enclosures are flange, throat, and air terminal chamber.

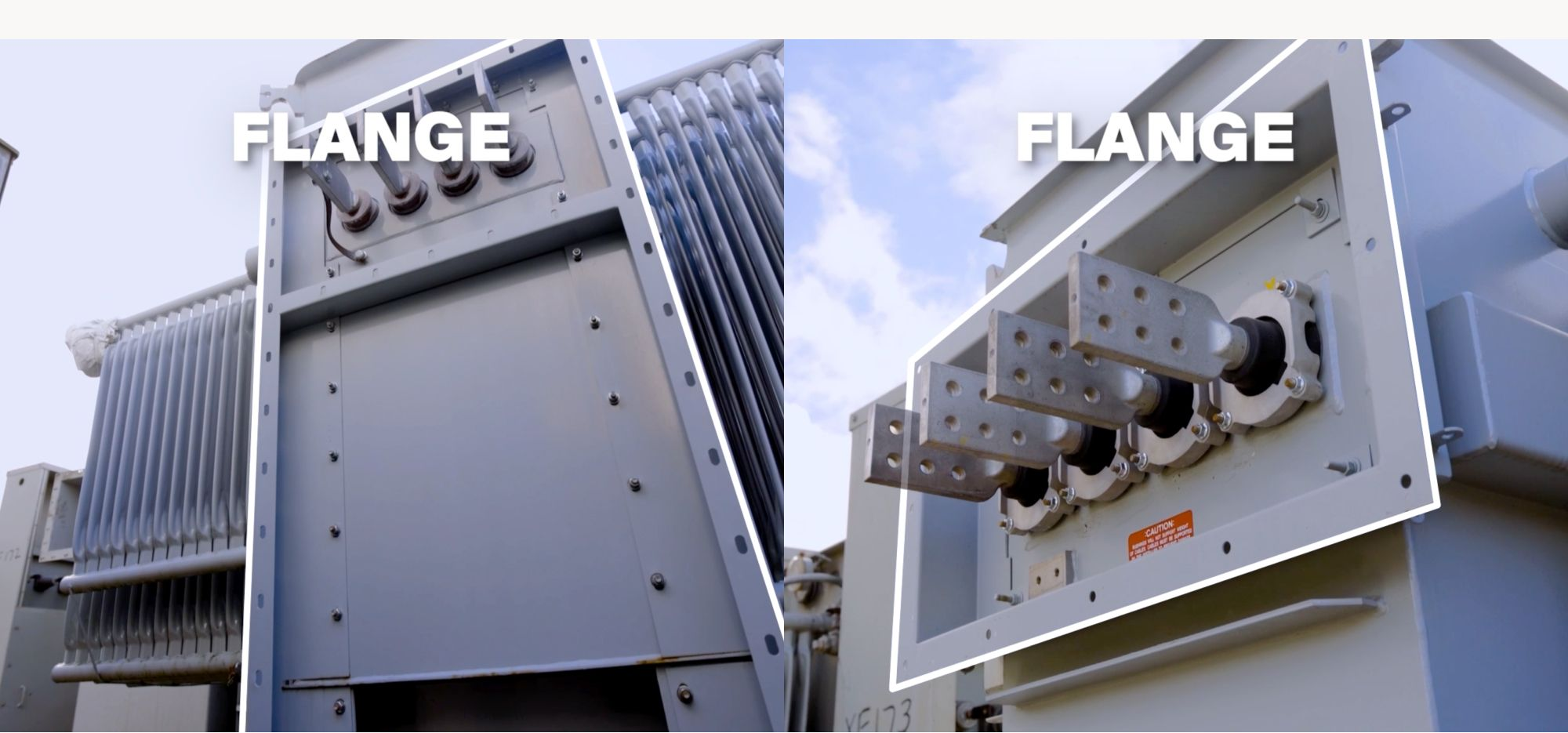

Flange

Flanges are typically used as just a mating section to bolt on an air terminal chamber or another transitional section. As pictured below, the transformer can be outfitted with a full-length flange (left) or a partial-length flange (right), which provides an interface on which you can bolt either a transition section or a bus duct.

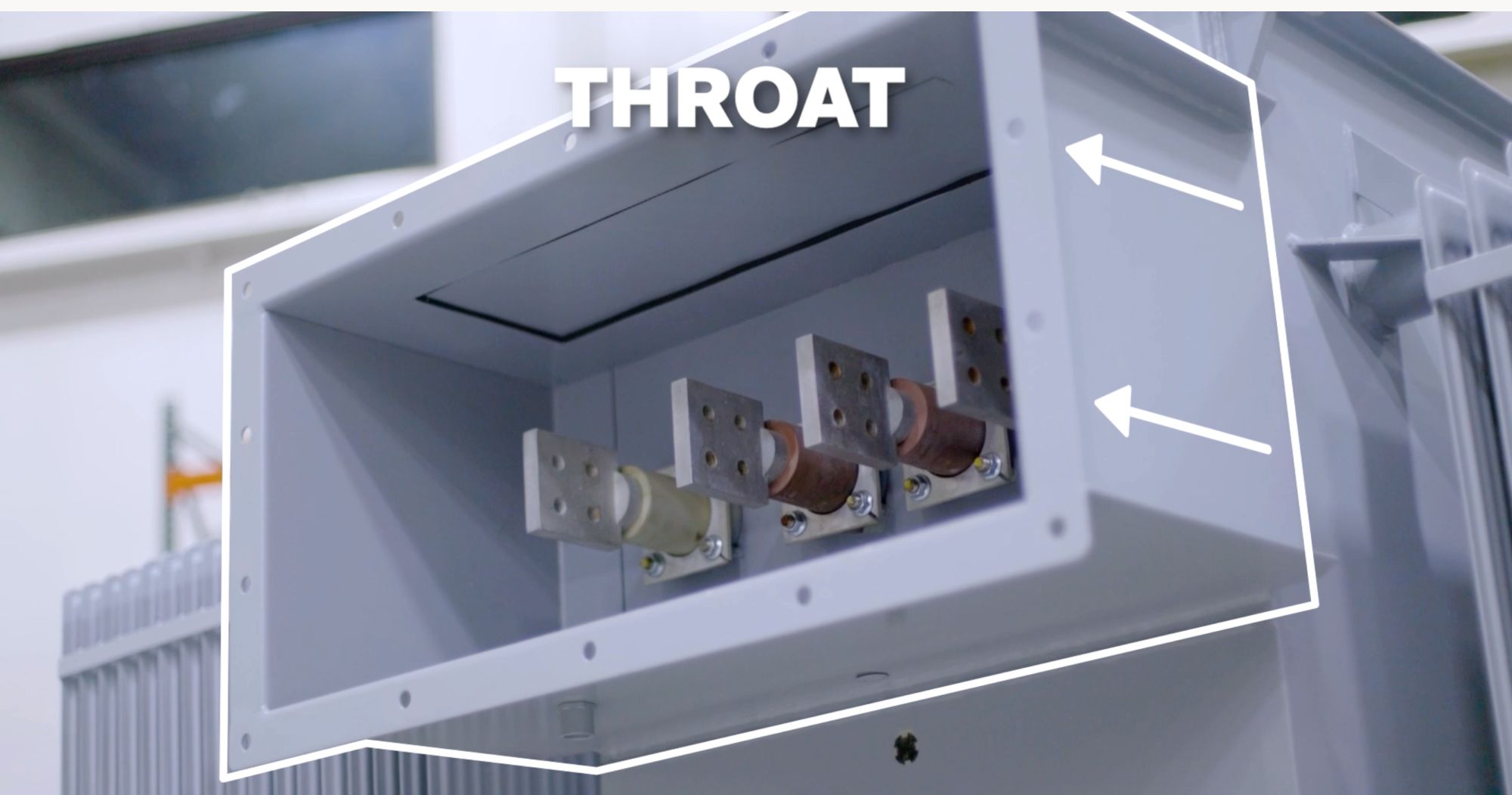

Throat

A throat is basically an extended flange, and as you can see in the image below, it can also connect directly to a bus duct or a piece of switchgear, just like a flange. Throats are usually located on the low-voltage side of a transformer. These are used when you need to connect a hard bus directly to the spades.

Throat

A throat is basically an extended flange, and as you can see in the image below, it can also connect directly to a bus duct or a piece of switchgear, just like a flange. Throats are usually located on the low-voltage side of a transformer. These are used when you need to connect a hard bus directly to the spades.

Post time: Sep-19-2024