In 2024, we delivered a 12 MVA transformer to the Philippines. This transformer features a rated power of 12,000 KVA and functions as a step-down transformer, converting a primary voltage of 66 KV to a secondary voltage of 33 KV. We utilize copper for the winding material due to its superior electrical conductivity, thermal efficiency, and resistance to corrosion.

Crafted with state-of-the-art technology and top-grade materials, our 12 MVA power transformer offers exceptional reliability and durability.

At JZP, we guarantee that every transformer we deliver undergoes a comprehensive acceptance test. We are proud to have maintained a flawless zero-fault record for over a decade. Our oil-immersed power transformers are engineered to meet the rigorous standards of IEC, ANSI, and other leading international specifications.

Scope of Supply

Product: Oil Immersed Power Transformer

Rated Power: Up to 500 MVA

Primary Voltage: Up to 345 KV

Technical Specification

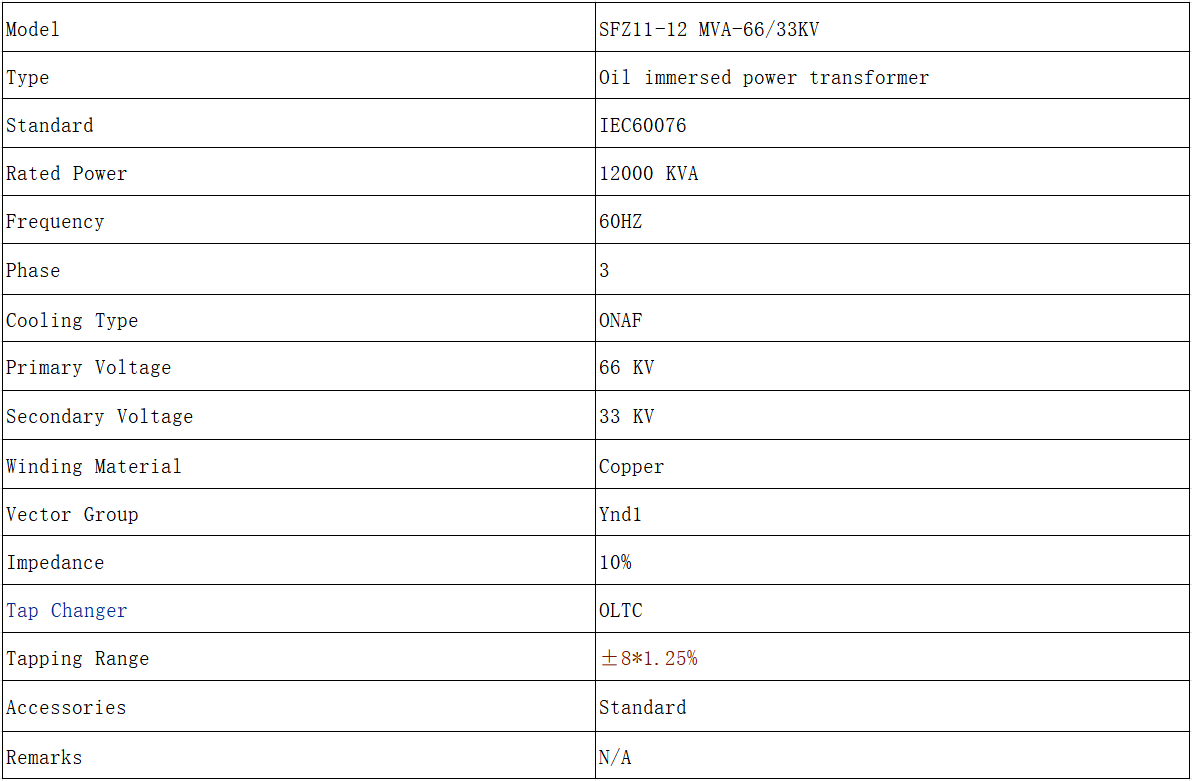

12 MVA power transformer specification and data sheet

The cooling method of an oil-immersed transformer typically involves using transformer oil as the primary cooling medium. This oil serves two main purposes: it acts as an electrical insulator and helps to dissipate heat generated within the transformer. Here are some common cooling methods used in oil-immersed transformers:

1. Oil Natural Air Natural (ONAN)

- Description:

- In this method, natural convection is used to circulate the oil within the transformer tank.

- The heat generated by the transformer windings is absorbed by the oil, which then rises and transfers the heat to the tank walls.

- The heat is then dissipated into the surrounding air through natural convection.

- Applications:

- Suitable for smaller transformers where the heat generated is not excessive.

- Description:

- This method is similar to ONAN, but it includes forced air circulation.

- Fans are used to blow air over the radiator surfaces of the transformer, enhancing the cooling process.

- Applications:

- Used in medium-sized transformers where additional cooling is required beyond natural air convection.

- Description:

- In OFAF, both oil and air are circulated using pumps and fans, respectively.

- Oil pumps circulate the oil through the transformer and radiators, while fans force air across the radiators.

- Applications:

- Suitable for large transformers where natural convection is insufficient for cooling.

- Description:

- This method uses water as an additional cooling medium.

- Oil is circulated through heat exchangers where water cools the oil.

- The water is then cooled through a separate system.

- Applications:

- Used in very large transformers or installations where space for air cooling is limited and higher efficiency is required.

- Description:

- Similar to OFAF, but with a more directed oil flow.

- The oil is directed through specific channels or ducts to enhance the cooling efficiency at particular hot spots within the transformer.

- Applications:

- Used in transformers where targeted cooling is needed to manage uneven heat distribution.

- Description:

- This is an advanced cooling method where oil is directed to flow through specific paths within the transformer, ensuring targeted cooling.

- The heat is then transferred to water via heat exchangers, with forced circulation to efficiently dissipate heat.

- Applications:

- Ideal for very large or high-power transformers in industrial or utility applications where precise temperature control is critical.

2. Oil Natural Air Forced (ONAF)

3. Oil Forced Air Forced (OFAF)

4. Oil Forced Water Forced (OFWF)

5. Oil Directed Air Forced (ODAF)

6. Oil Directed Water Forced (ODWF)

Post time: Jul-29-2024